Heat Technology Laboratory

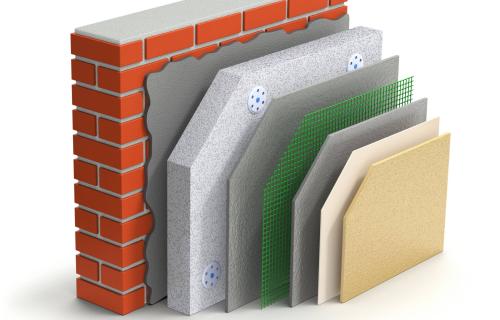

The Heat Transmission section deals mainly with the thermal characterization of building envelope elements.

This characterization can be carried out by laboratory tests, in field tests and by theoretical models.

These activities are carried out according to national, European and international standards or, in absence of applicable standards, according to customer specifications.

The section is made of highly qualified personnel with a long experience in the field of thermal properties of materials.

The laboratory realizes a quality management system according to the EN ISO/IEC 17025 standard and is also ACCREDIA LAB N at 0021 accredited for testing of:

This characterization can be carried out by laboratory tests, in field tests and by theoretical models.

These activities are carried out according to national, European and international standards or, in absence of applicable standards, according to customer specifications.

The section is made of highly qualified personnel with a long experience in the field of thermal properties of materials.

The laboratory realizes a quality management system according to the EN ISO/IEC 17025 standard and is also ACCREDIA LAB N at 0021 accredited for testing of:

- thermal resistance and thermal conductivity by the hot plate method with guard ring

- determination of water absorption properties by immersion and diffusion

- determination of dimensional characteristics

- numerical simulations for the determination of thermal performances of building elements

Do you need more information about our services?

Do you need more information about our services?