Optical tests in the railway sector

(Pubbl. 06/09/2024)Istituto Giordano’s optical laboratory carries out tests on windscreens and train windows in accordance with the main Italian and international standards. The tests include:

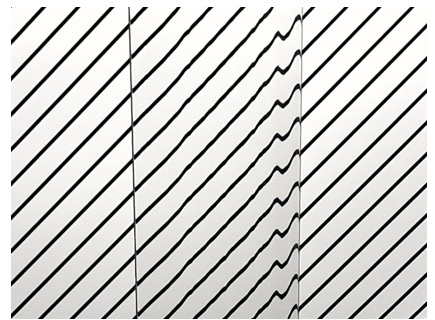

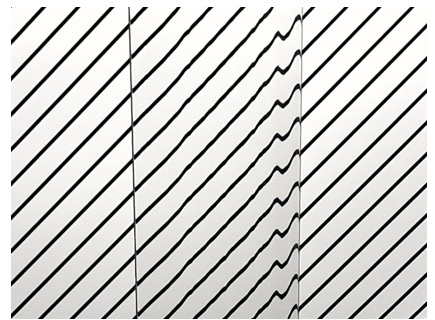

The purpose of the test is to verify that glass manufacturing processes such as tempering or laminating do not cause distortion of the image seen through the glass due to inhomogeneities in the product. The test consists of placing the glass in front of a screen with black and white stripes at an angle of 45°. The product is placed on a rotating stand and rotated around the vertical axis until the limit angle is found beyond which the glass distorts the screen lines. The reference standards specify the limit for this angle of rotation to de-termine whether or not the glass conforms to the standard. An example of a zebra test where the screen lines are distorted is shown in Figure 1.

ISO 3538 provides two tests for assessing optical distortion and secondary image separation.

The first consists of projecting an array of light dots of a standard diameter and spacing onto the glass and inspecting the diameter of these dots on a screen after the image has passed through the glass (Figure 2).

Optical distortion results in a change in the diameter of the dots, which is measured by the laboratory tech-nician and compared with regulatory limits to determine product compliance.

The second is to check that the glass does not produce a “ghost” image of light sources outside the train, such as traffic lights along the track or the lights of another train. To check this, the laboratory is equipped with a lighting device that produces a “ring and spot” image, i.e. consisting of a luminous circle and a lumi-nous ring concentric with the circle (Figure 3).

The observer looks at the image through the glass and notes whether there is a ghost image of the circle of light produced by the glass. The test is passed if there is no ghost image or, if there is, the image does not leave the perimeter defined by the ring of light.

Transmittance measures the percentage of visible light that passes through the glass, while chromaticity describes the colour of the tested light in numerical coordinates. Haze quantifies the opacity of the glass. Measurements are made using a spectrophotometer, which analyses the light transmitted through a sam-ple of glass, and the results are compared with the limits set by the standards.

Istituto Giordano’s optical and chemical laboratories work in synergy to determine the glass’s ability to re-sist agents that cause abrasion and ageing, simulating these processes with special machines and compar-ing the optical properties measured before and after the process to assess the product’s response. Specifi-cally, the abrasion test involves measuring haze before and after abrasion using Taber-type equipment to quantify the increase in haze caused by abrasion. The ageing test involves measuring light transmission and calculating the “yellow index” before and after accelerated ageing in a UV condensation chamber. The deterioration of the material due to ageing is quantified by the change in the yellow index. The reference standard sets maximum limits for haze and yellow index variation to establish product conformity.

To view all our activities in the railway sector, please visit the dedicated page "Laboratory Tests in the Railway Sector."

- Aesthetic quality;

- Optical distortion;

- Secondary image separation;

- Light transmission;

- Chromaticity

- Haze;

- Abrasion resistance;

- Resistance to ageing.

Aesthetic quality

Several methods are used to assess the aesthetic quality of railway glass. The best known of these is the “zebra test”, regulated by standards NF F 31-129 (tempered glass) and NF F 31-250 (laminated glass).The purpose of the test is to verify that glass manufacturing processes such as tempering or laminating do not cause distortion of the image seen through the glass due to inhomogeneities in the product. The test consists of placing the glass in front of a screen with black and white stripes at an angle of 45°. The product is placed on a rotating stand and rotated around the vertical axis until the limit angle is found beyond which the glass distorts the screen lines. The reference standards specify the limit for this angle of rotation to de-termine whether or not the glass conforms to the standard. An example of a zebra test where the screen lines are distorted is shown in Figure 1.

Optical distortion and secondary image separation

ISO 3538 provides two tests for assessing optical distortion and secondary image separation.The first consists of projecting an array of light dots of a standard diameter and spacing onto the glass and inspecting the diameter of these dots on a screen after the image has passed through the glass (Figure 2).

Optical distortion results in a change in the diameter of the dots, which is measured by the laboratory tech-nician and compared with regulatory limits to determine product compliance.

The second is to check that the glass does not produce a “ghost” image of light sources outside the train, such as traffic lights along the track or the lights of another train. To check this, the laboratory is equipped with a lighting device that produces a “ring and spot” image, i.e. consisting of a luminous circle and a lumi-nous ring concentric with the circle (Figure 3).

The observer looks at the image through the glass and notes whether there is a ghost image of the circle of light produced by the glass. The test is passed if there is no ghost image or, if there is, the image does not leave the perimeter defined by the ring of light.

Light transmission, colour and haze

These tests measure how much light the glass transmits, how the colour of the light that passes through it changes and how sharp the image visible on the other side is.Transmittance measures the percentage of visible light that passes through the glass, while chromaticity describes the colour of the tested light in numerical coordinates. Haze quantifies the opacity of the glass. Measurements are made using a spectrophotometer, which analyses the light transmitted through a sam-ple of glass, and the results are compared with the limits set by the standards.

Testing resistance to abrasion and ageing

Train windows are subject to abrasion from particles in the air and from cleaning processes; exposure to atmospheric agents such as ultraviolet radiation can also degrade the product, especially in the case of lam-inated glass with plastic interlayers.Istituto Giordano’s optical and chemical laboratories work in synergy to determine the glass’s ability to re-sist agents that cause abrasion and ageing, simulating these processes with special machines and compar-ing the optical properties measured before and after the process to assess the product’s response. Specifi-cally, the abrasion test involves measuring haze before and after abrasion using Taber-type equipment to quantify the increase in haze caused by abrasion. The ageing test involves measuring light transmission and calculating the “yellow index” before and after accelerated ageing in a UV condensation chamber. The deterioration of the material due to ageing is quantified by the change in the yellow index. The reference standard sets maximum limits for haze and yellow index variation to establish product conformity.

To view all our activities in the railway sector, please visit the dedicated page "Laboratory Tests in the Railway Sector."

Do you need more information about our services?

Do you need more information about our services?